Many modern motorcycles look similar because they are made to appeal to everyone. This means they often do not have much personality or bold style. That is why this project stands out. It was built to break the rules and show what a custom bike can really be. The team behind this bike wanted something special, something that would grab attention and show off their own ideas.

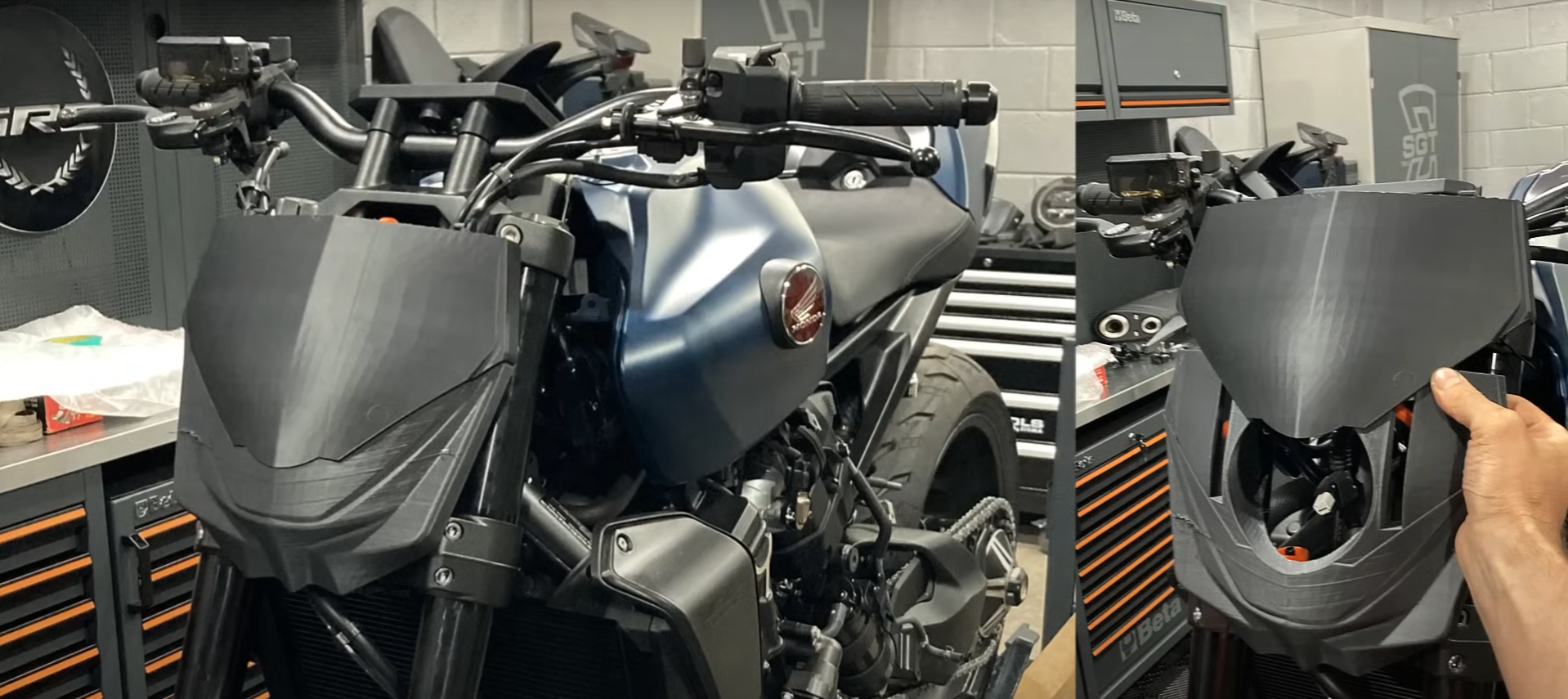

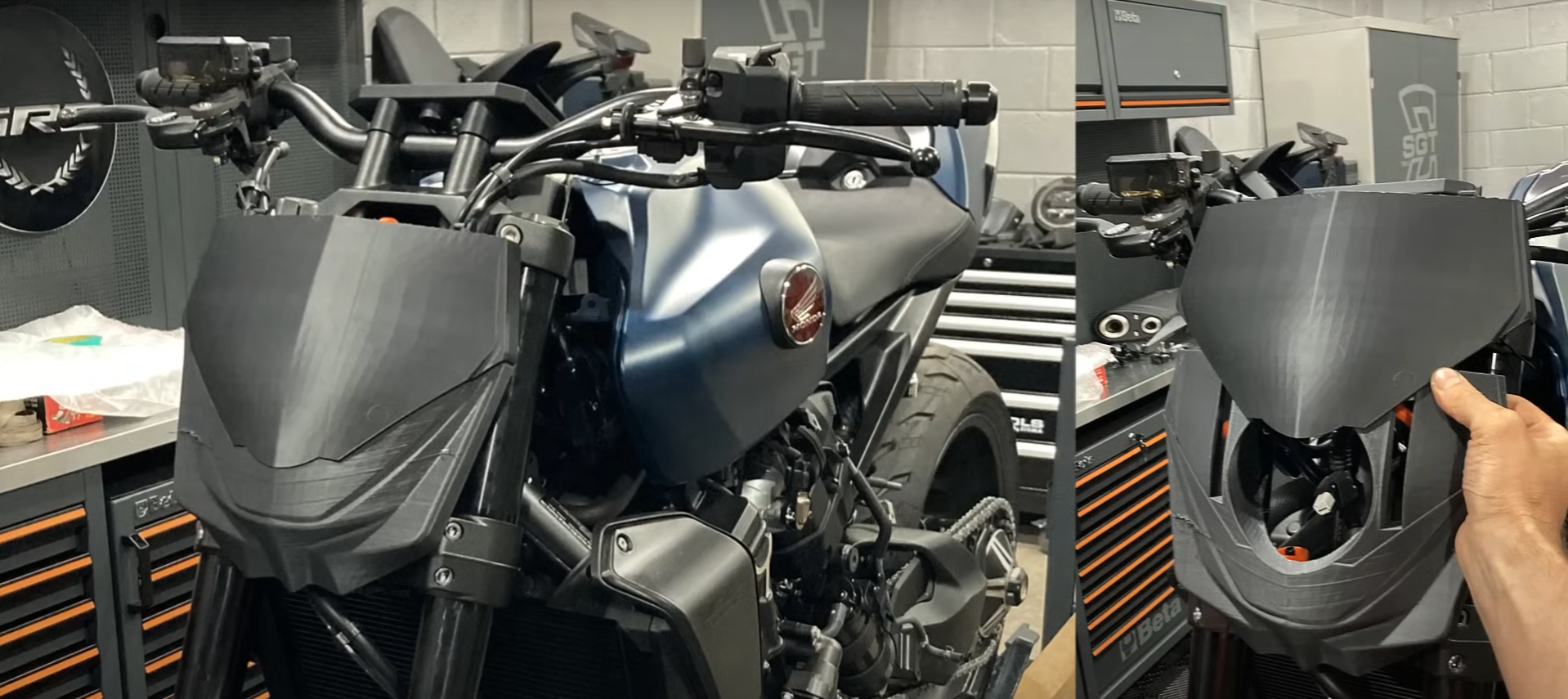

The Honda CB 1000R was turned into a true one-of-a-kind machine by Sebastián Rochon from SR Corse and artist Prozak in Brazil. They worked with sponsors and used 3D printing to create new parts, from the rear cowl to small design details. The motorcycle keeps its strong engine but now has a fresh, creative look that makes it different from anything else on the road.

Key Takeaways

- This project began as a bold effort to stand out from ordinary bikes

- Creators used custom parts and creative ideas to change the Honda CB 1000R

- The team overcame challenges and built a unique motorcycle in a short time

Project Overview

Why Stand-Out Motorcycles Matter

Many modern motorcycles are designed to please as many people as possible. This often leads to bikes that look similar and lack personality. They may be fast and new, but they do not always turn heads or spark interest. Some riders want something different—a motorcycle that shows style and attitude.

| Common Motorcycle Features | Unique Bike Features |

|---|---|

| Simple styling | Bold, creative designs |

| Mass appeal | Stand-out appearance |

| Standard parts | Custom and hand-made pieces |

SR Corse’s Bold Custom Build

The motorcycle project featured here was built to be different. SR Corse, led by Sebastián Rochon, joined forces with artist Prozak in Brazil to bring this idea to life. They took part in a special program from Honda Brazil, allowing teams to freely customize four bikes. This build stands out with a custom 3D-printed rear section, a special frame, and many hidden details.

Important changes include:

- Custom aluminum subframe

- Handmade exhaust with loud mufflers

- Hidden turn signals and smart design touches

The creators wanted a motorcycle that did not follow the usual rules. The goal was to make a bike that was eye-catching, fun, and bold, not just another model on the street. Even with a short deadline, SR Corse delivered a unique bike full of character and energy.

People Behind the Build

Sebastián Rochon and SR Corse Team

Sebastián Rochon, who started SR Corse, is from Uruguay but works in Brazil. He led the work on the custom Honda and came up with many of the ideas that make it stand out. His team used parts made with 3D printing, tried several versions, and focused on small details like the rear cowl and custom subframe. Sebastián wanted the bike to look unique, even if it meant making bold and risky choices. He was also careful about what to keep original, like leaving the engine alone.

Art by Prozak

The motorcycle features special art from a creator known as Prozak. He worked on the design, including the top of the fuel tank. The artwork honors Honda’s history and adds a personal touch to the build. His style helped make the bike even more unusual and gave it attitude.

Backing from Honda Brazil

Honda Brazil helped support the project and started the “Wing Crafters” program. They brought together customizers and artists as teams and gave them the chance to rebuild four different Hondas. Thanks to their support, Sebastián and Prozak had the resources and room to create their vision.

How the Bike Was Made Unique

How the Build Changed Over Time

The Honda CB 1000R went through many changes during the build. At first, there was a plan to make it look more like a Cafe Racer with a semi-fairing. But the design direction switched to something less basic. Many parts, like the rear end and taillight, were made with 3D printing. There were multiple tries to get it right, not just one. Small details, like a see-through volume on the rear cowl, added to the fresh look. The bike also got a custom aluminum subframe with a special “Ducati” style.

Key Changes:

- 3D printed rear cowl and taillight

- Custom aluminum subframe

- Camouflage box for the electrical system

- Hidden turn signals

Inspired by Hooligan and Naked Bikes

This bike does not follow the Cafe Racer style. Instead, it was made to feel more like a tough street bike—kind of wild and bold. The look is meant to stand out and be a bit daring, like a “Streetfighter.” Unique choices set it apart, such as a special rear wheel cover and bold side details by the radiator. The project aimed for something that would not look boring next to other bikes.

Features:

- Turbofan-style rear wheel cover

- Special panels near the radiator

- Hidden front suspension height

- Ducati front fender

- Handmade stainless steel exhaust with Arrow mufflers

Built for Fun on the Track and Everyday Riding

The idea for the bike was to make something that would work both for track days and for normal street rides. It was designed with a number plate on the front, giving it a motorsport vibe but still practical for daily use. Not all race ideas were possible because the build had a 90-day deadline. For example, there was a plan for a headlight that would pop up with a button, but there was not enough time to finish it. Still, the result is a bike that looks special and can do more than just one thing.

| Purpose | Features Included |

|---|---|

| Track Days | Number plate, sporty changes, strong brakes |

| Daily Riding | All needed lights, comfortable setup |

| Both Uses | Powerful, stylish, and easy to ride |

Main Upgrades

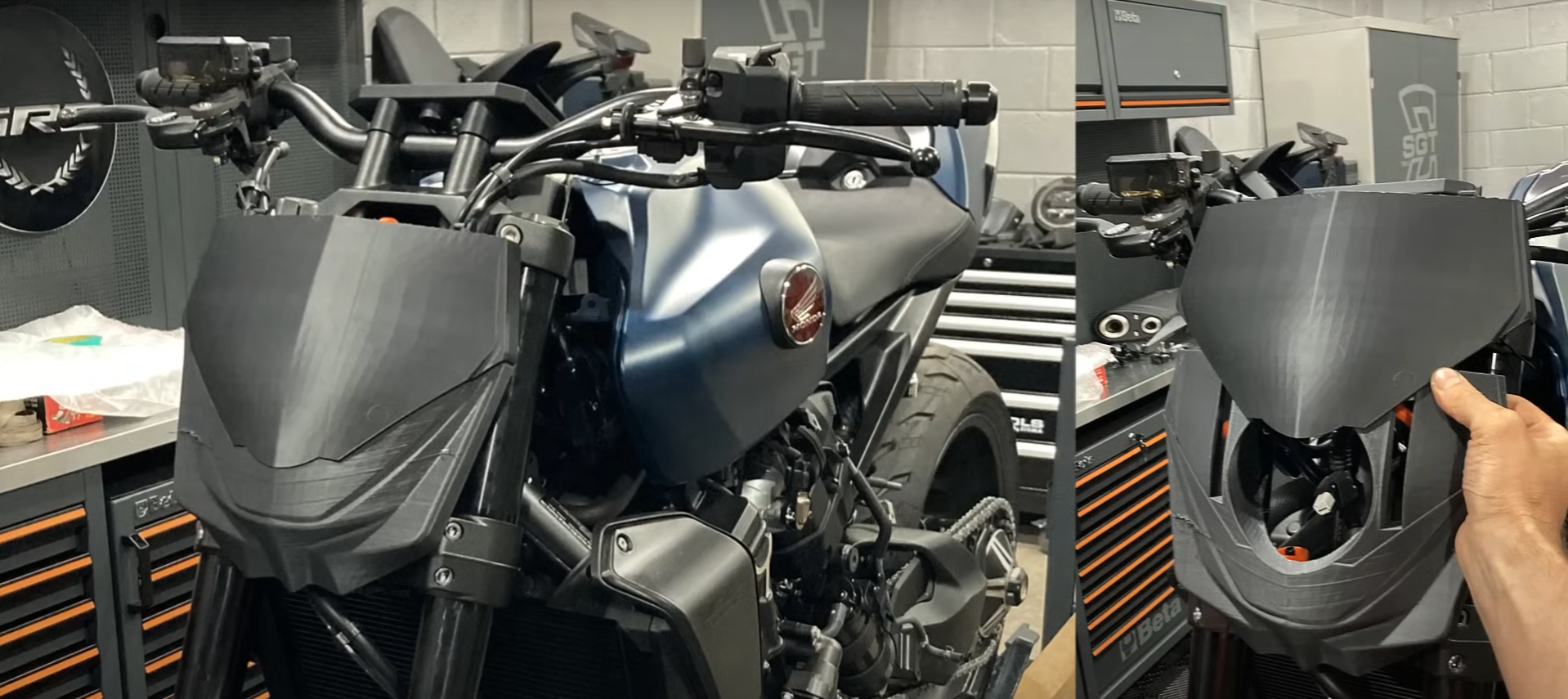

3D-Printed Parts

The back end stands out with custom 3D-printed pieces, including the taillight. Several sections were made and joined together, each made to fit perfectly. One piece even uses see-through material, making the design unique. The work took a few tries, but the final pieces look smooth and modern.

Key Features:

- Fully 3D-printed rear cowl and taillight

- Multiple attachable parts for a detailed look

- Special transparent part adds style

| Part | Material | Special Feature |

|---|---|---|

| Rear Cowl | Plastic/Resin | Bolt-on design |

| Taillight | Plastic | 3D printed, custom shape |

| Accent Piece | Transparent | Adds subtle volume |

Custom Metal Frame Under the Seat

A brand-new aluminum frame was built to hold up the seat area. It is made from metal tubes and is not the usual style found on most bikes. This piece gives the motorcycle a different look, more like some stylish Italian bikes. Even though removing some systems proved difficult, steps were taken to hide the wires and keep things neat.

- Strong aluminum tubing for support

- Stylish design with special “Ducati” feel

- Hidden compartment to keep wiring clean

Hand-Built Stainless Exhaust

Instead of using the standard parts, the exhaust system was made by hand using stainless steel. New mufflers from Arrow were fitted to give a powerful sound and add a sporty touch. This change is both for looks and noise.

Highlights:

- Fully handmade pipe system

- Loud Arrow mufflers included

- Shiny finish gives a custom look

Distinctive Back Wheel and Cooling Add-Ons

The back wheel features a bold cover that looks like a jet turbine. Not everyone will love it, but it sure catches the eye. Next to the radiator, custom covers help with style and airflow. This area also hides some turn signals, making the design sleek. The front fender comes from a different brand, adding even more character.

- Eye-catching rear wheel disc

- Custom radiator shrouds

- Hidden turn signals for a tidy look

- Upgraded front fender not from original bike

Unique Design Elements

New Style Front Light System

The front headlight on this motorcycle is different from most others. There were plans to hide the headlight behind a top cover that would slide away using a small electric motor. The rider could make the headlight show just by pressing a button. This idea would have made the bike stand out even more, but because the build only lasted 90 days, the final motorized setup could not be finished and a simpler headlight was used for now.

Artist Signature on Gas Tank

The fuel tank features artwork by the artist Prozak. His design on the tank tells a story and links back to Honda’s history of being bold and creative. This artwork gives the motorcycle a personal and unique touch. The top of the tank becomes more than just a place for fuel—it’s also a small canvas that shows the spirit behind the project.

Difficulties Faced and How They Were Handled

Limited Time to Finish

Finishing the whole motorcycle build in just 90 days was a big challenge. There was not much room for mistakes or delays. Some creative ideas, like a hidden front headlight with a sliding cover and electric motor, could not be finished because there was not enough time.

Key ways they dealt with the short deadline:

- Used simpler solutions when needed

- Focused on the most important features first

- Made smart choices on what changes could be finished on time

| Problem | How They Handled It |

|---|---|

| Not enough time | Chose quicker solutions, prioritized tasks |

| Unfinished design | Picked simpler options for key parts |

Solving Design and Technical Issues

Making custom pieces fit the bike brought other problems. The team used 3D printing for making the tail and details, but it took many tries to get it just right. Not every part worked out on the first or even third try. Adjustments were needed, especially when fitting new pieces with the original frame.

Ways they solved technical issues:

- Tried different shapes and materials

- Used custom-built parts, like the tubular subframe

- Added clever details, such as hiding electrical parts in a special box

- Handcrafted exhaust system for a unique look and sound

They made bold design choices, like the rear wheel cover and hidden turn signals. Some changes were not simple, but creativity and patience helped make the vision real.

Personal Reflections

This motorcycle stands out with bold style and a strong attitude. It avoids the usual safe choices seen in most bikes today. Each part, from the 3D printed rear to the unique subframe, was built to be noticed.

Working with different artists and sponsors allowed for full creative freedom. Some features, like hidden turn signals and custom exhausts, show careful attention to every detail. Even small pieces, like the semi-transparent 3D printed parts, add a special touch.

The bike mixes power with standout looks. It’s not trying to fit into one style, and that’s what makes it interesting. Even unfinished ideas, like the electric headlight cover, show a willingness to try new things.

Here’s a quick look at what makes this project unique:

| Feature | Details |

|---|---|

| Custom rear end | 3D printed, includes taillight and subtle details |

| Unique subframe | Aluminum, custom-made with a “Ducati” vibe |

| Rear wheel & radiator covers | Bold, with hidden touches for cleaner design |

| Front fender & exhaust | Ducati fender, hand-built exhaust with Arrow parts |

| Headlight idea | Planned electric cover didn’t make deadline |

| Art on tank | Honoring Honda’s creative spirit |

Thanks to all who helped bring this bold project to life. It took talent and courage to create something so different.